Optosensors

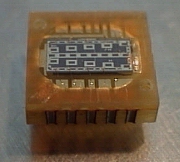

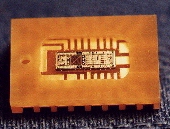

A customer-specific optosensor mainly consists of a chip carrier and a plastic housing. The housing must meet many various conditions. Filter action, for instance, shall prevent the influence of extraneous light.

A local resolution of the measuring beam should be possible, for instance for paper edge measurements and hair sensors.

Based on your specifications we develop housings for existing chip carriers, or we design the entire sensor for you, including the glas fibre applications.

A local resolution of the measuring beam should be possible, for instance for paper edge measurements and hair sensors.

Based on your specifications we develop housings for existing chip carriers, or we design the entire sensor for you, including the glas fibre applications.

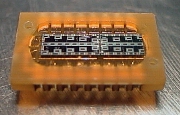

Optoschmitt chips are very efficient in the encoder field. A complete sensor for encoder applications consists of a carrier material receiving the Optoschmitt chips, a frame and a clear encapsulant protecting the sensitive semiconductor materials. Contacting is made by edge contacts (SDM technology).

We can assist you for encoder applications. Our range: professional service from the design of specially tuned sensors to ASIC development.

We can assist you for encoder applications. Our range: professional service from the design of specially tuned sensors to ASIC development.

High resolution, fault-finding edge detector

Edge detector for position measurement without Hysteresis

The newly developed STM 100 edge detecting sensor detects the leading and trailing edge of an object. Both sensor and signal processing electronics are integrated into an intelligent compact chip. The sensor is suitable for accurately positioning objects, measuring lengths, time and velocity, for the object flow control and to monitor the process.

Thus it can be used to detect a broken thread or to monitor webs of textiles, film or paper. The sensor has been designed for industrial use on objects with high velocities and transparent media.

A spectacular feature is its extremely precise resolution of less than 10µm.

Edge detector for position measurement without Hysteresis

The newly developed STM 100 edge detecting sensor detects the leading and trailing edge of an object. Both sensor and signal processing electronics are integrated into an intelligent compact chip. The sensor is suitable for accurately positioning objects, measuring lengths, time and velocity, for the object flow control and to monitor the process.

Thus it can be used to detect a broken thread or to monitor webs of textiles, film or paper. The sensor has been designed for industrial use on objects with high velocities and transparent media.

A spectacular feature is its extremely precise resolution of less than 10µm.

The customer-specific opto-sensors with integrated optics and microelectronics (COB-technology or ASIC), made from special synthetic materials, are in series production. First sensor samples are made from metal, or from synthetic material with a RPC (Rapid Prototyping) process.

One of our main activities, for instance, is the development of customer-specific photodiode arrays.

These arrays are used in encoder production and as measuring sensors. The electrical parameters and the housing sizes are defined in mutual agreement with the customer.

Optimum adaptation to the particular measuring task is obtained by using existing photo diode semiconductors, or by designing new ones.

These arrays are used in encoder production and as measuring sensors. The electrical parameters and the housing sizes are defined in mutual agreement with the customer.

Optimum adaptation to the particular measuring task is obtained by using existing photo diode semiconductors, or by designing new ones.

Often the differential light priciple is used in sensor systems. It offers the advantage of being independent of surrounding light disturbances. At the same time the differential light sensor guarantees a certain local resolution, thereby reducing housing development cost.

We can design individual high-resolution sensors for you by assembling differential optochips with integrated Schmitt trigger.

We can design individual high-resolution sensors for you by assembling differential optochips with integrated Schmitt trigger.